2021 Good Quality Fine Cleaning Machine - 10C Air screen cleaner – Taobo

2021 Good Quality Fine Cleaning Machine - 10C Air screen cleaner – Taobo Detail:

Introduction

The seed cleaner and grains cleaner it can remove the dust and light impurities by vertical air screen , Then vibrating boxes can remove the big and small impurities , and Grains and seeds can be separated big ,medium and small size by different sieves . and it can remove the stones .

Features

● The seed and grains air screen cleaner consists of dust collector , Vertical screen, vibration box sieves and Non-broken low speed bucket elevator.

● It is widely used in seed processing and grains processing plant and Pulses processing plant as the Pre-cleaner.

● The material can be classified into big, medium and small particles with different layers of sieves ( Stainless steel sieves ).

Advantage

● High Purity :98%-99% purity

● 5-10Ton per hour cleaning capacity for cleaning different seeds and clean grains.

● Non broken low speed bucket elevator without any damage for the seeds and grains.

● High quality motor for seeds cleaning machine ,high quality Japan bearing .

● Easy to operate with high performance .

Details show

Japan bearing

Brand motor

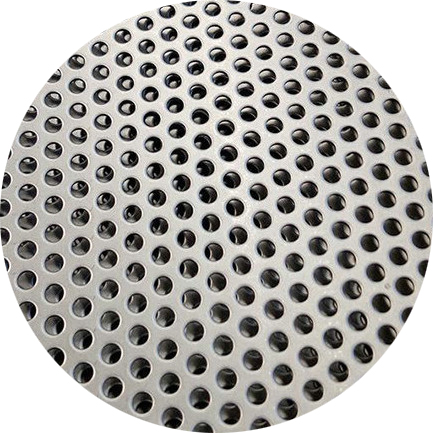

stainless steel sieve

Technical specifications

|

Name |

Model |

Size of sieves(mm) |

Layer |

Capacity (T/H) |

Weight(T) |

Oversize L*W*H(MM) |

Power(KW) |

Voltage |

|

Air screen cleaner |

5TB-5B |

1000*2000 |

Three |

5 |

1.5 |

4500*1800*3400 |

7.5 |

380V 50HZ |

|

5TB-5C |

1000*2000 |

Four |

5 |

1.53 |

4500*1800*3400 |

7.5 |

380V 50HZ |

|

|

5TB-7.5B |

1250*2400 |

Three |

7.5 |

1.8 |

5100*2050*3450 |

8.5 |

380V 50HZ |

|

|

5TB-7.5C |

1250*2400 |

Four |

7.5 |

1.83 |

5100*2050*3450 |

8.5 |

380V 50HZ |

|

|

5TB-10C |

1500*2400 |

Four |

10 |

2.0 |

5100*2300*3600 |

10.5 |

380V 50HZ |

|

|

5TB-10D |

1500*2400 |

Five |

10 |

2.2 |

5100*2300*3600 |

10.5 |

380V 50HZ |

Questions from clients

What material the seed cleaner can clean ?

It can clean most of seeds and grains,Beans and so on,it can improve the purity of agro products,Most Agro exporters are using our cleaner for satisfied with the goverment customer for exporting .

What is the capacity for the cleaner ?

Normally it can upto 5-10tons per hour cleaning seeds and grains . Generally it depends on what material you want to clean,Because different material the processing effency it is difference .

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for 2021 Good Quality Fine Cleaning Machine - 10C Air screen cleaner – Taobo , The product will supply to all over the world, such as: Turkey, Juventus, Kuala Lumpur, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!