Best quality Grain Grading And Cleaning Machine - Grains cleaning line & grains processing plant – Taobo

Best quality Grain Grading And Cleaning Machine - Grains cleaning line & grains processing plant – Taobo Detail:

Introduction

The capacity: 2000kg- 10000kg per hour

It can clean seeds, sesame seeds, beans seeds, groundnuts seeds, chia seeds

The seeds processing plant include the machines as below.

Pre-cleaner : 5TBF-10 air screen cleaner

Clods removing : 5TBM-5 Magnetic Separator

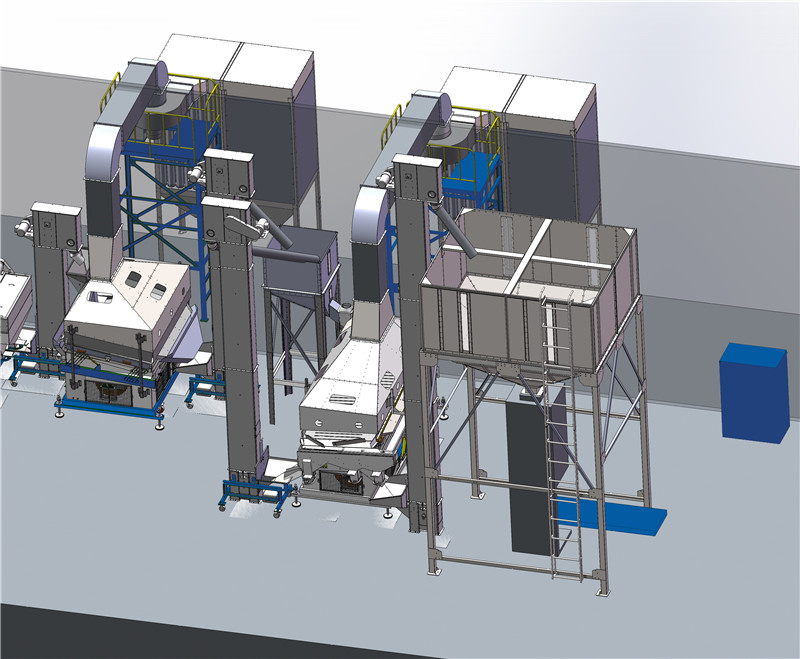

Stones removing : TBDS-10 de-stoner

Bad seeds removing : 5TBG-8 gravity separator

Elevator system : DTY-10M II elevator

Packing system : TBP-100A packing machine

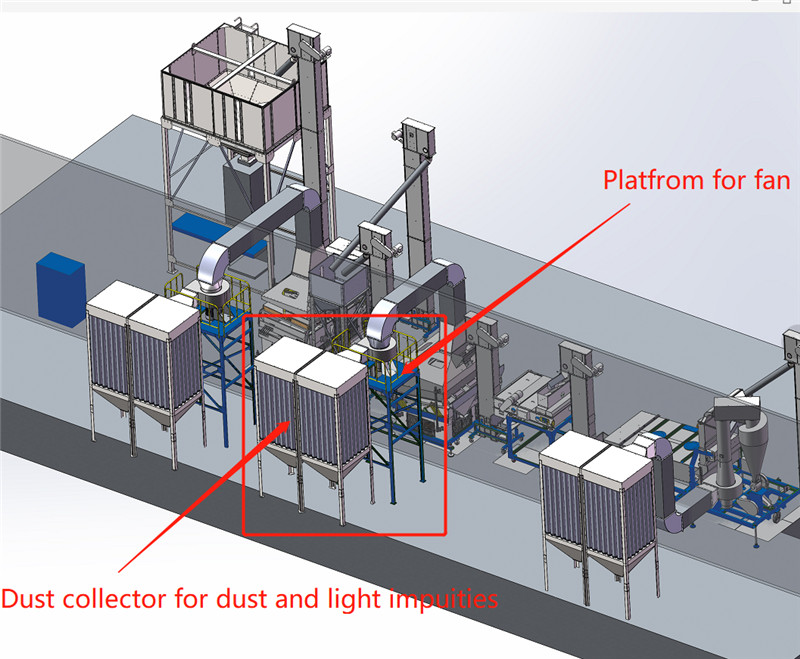

Dust collector system : Dust collector for each machine

Control system :Auto control cabinet for the whole seeds processing plant

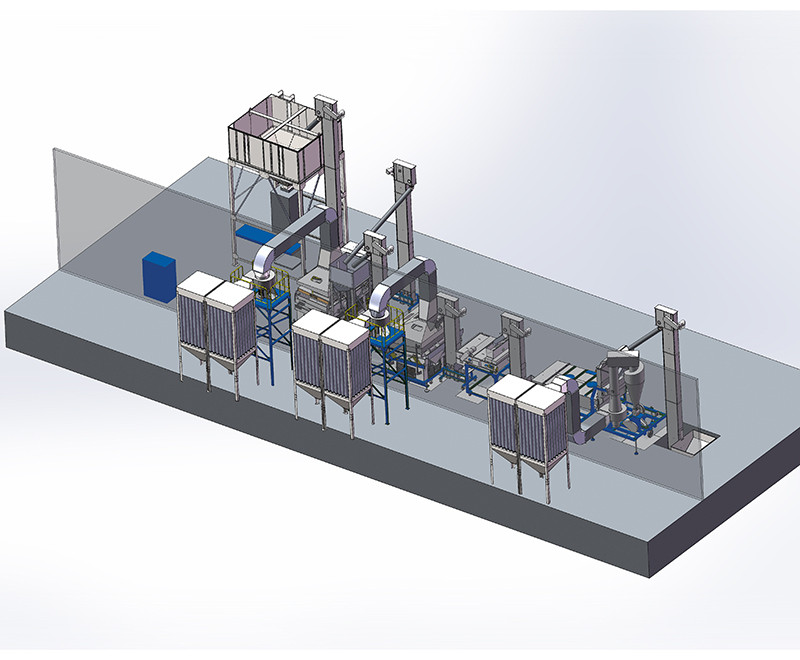

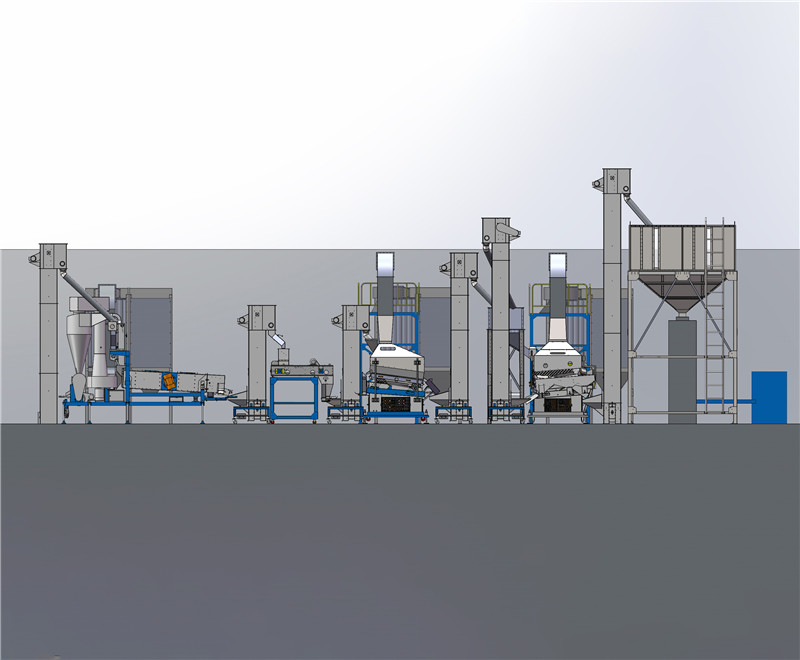

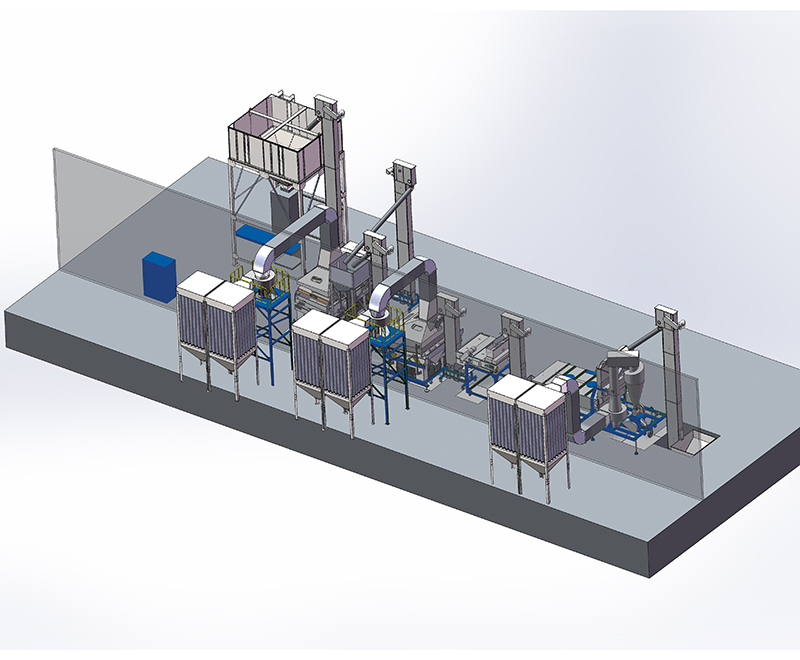

Layout of sesame cleaning plant

Features

● Easy to operate with high performance .

● Environmental cyclone duster system to protect clients warehouse .

● 2-10 Ton per hour cleaning capacity for cleaning all different seeds .

● High quality motor for seeds cleaning machine, high quality Japan bearing .

● High Purity :99.99% purity especially for cleaning sesame, groundnuts beans

Each machine showing

Air screen cleaner

To remove large and small impurity, dust, leaf, and small seed etc..

As the pre-cleaner in the Seed cleaning line & seed processing plant

De-stoner machine

TBDS-10 De-stoner type blowing style

Gravity destoner can remove the stones from different seeds with high performance

Magnetic separator

It remove all metals or magnetic clods and soils from beans, sesame and other grains . It is very popular in Africa and Europe.

Gravity separator

Gravity separator can remove the blighted seed, budding seed, damaged seed, injured seed, rotten seed, deteriorated seed, moldy seeds from sesame, Beans Groundnuts and with high performance.

Auto packing machine

Function :The auto packing machine used for packing the beans, grains, sesame seeds and maize and so on, From 10kg-100kg per bag, electronic controlled automatic

Cleaning result

Raw grains

Impuities

Good grians

Technical specifications

| No. | parts | Power (kW) | Load rate % | Power consumption kWh/8h |

Auxiliary energy | remark |

| 1 | Main machine | 30 | 71% | 168 | no | |

| 2 | Lift and convey | 4.5 | 70% | 25.2 | no | |

| 3 | Dust collector | 15 | 85% | 96 | no | |

| 4 | others | <3 | 50% | 12 | no | |

| 5 | total | 49.5 | 301.2 |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Best quality Grain Grading And Cleaning Machine - Grains cleaning line & grains processing plant – Taobo , The product will supply to all over the world, such as: Liberia, Dubai, Morocco, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.