China Factory for Pulses And Beans Cleaning Line - Pulses and beans processing plant and pulses and beans cleaning line – Taobo

China Factory for Pulses And Beans Cleaning Line - Pulses and beans processing plant and pulses and beans cleaning line – Taobo Detail:

Introduction

The capacity: 3000kg- 10000kg per hour

It can clean mung beans, soya beans, beans pulses, coffee beans

The processing line include the machines as below.

5TBF-10 air screen cleaner as the Pre-cleaner remove the dust and lager and smaller impurities, 5TBM-5 Magnetic Separator remove the clods, TBDS-10 De-stoner remove the stones, 5TBG-8 gravity separator remove the bad and broken beans, Polishing machine remove the dust of beans surface. DTY-10M II elevator loading the beans and pulses to the processing machine, Color sorter machine remove the different color beans and TBP-100A packing machine in the final section pack bags for loading containers, Dust collector system for keep warehouse clean.

Introduction

SUITABLE : We will design the beans and pulses processing plant as your warehouse size, You can send us the layout for your warehouse, then we design the cleaning area, the good stock area, the working area, Until we offer the best design for you.

SIMPLE : We will design one control system for you to control the whole beans plant, so that to achieve one key running and one key off. For the install we can arrange our engineer to do the installation for you.

CLEAN: The processing line have the dust collecting parts for every machine. It will be good for the environment of the warehouse. Keep clean for your warehouse.

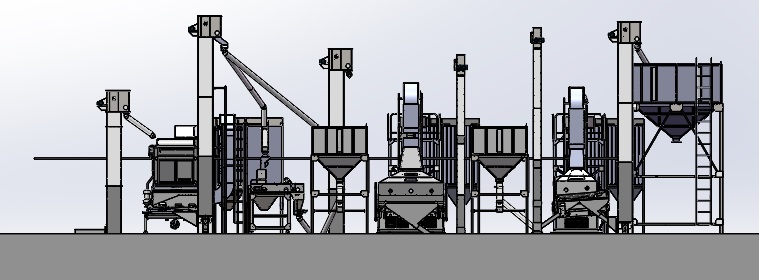

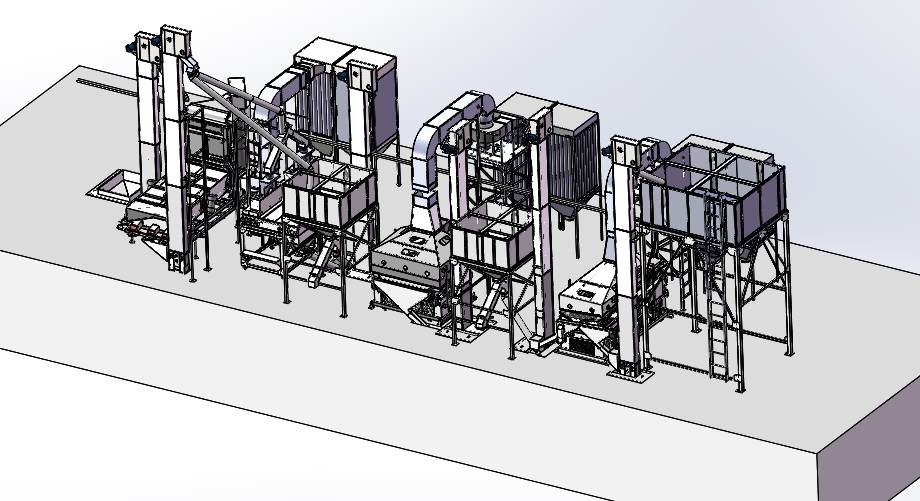

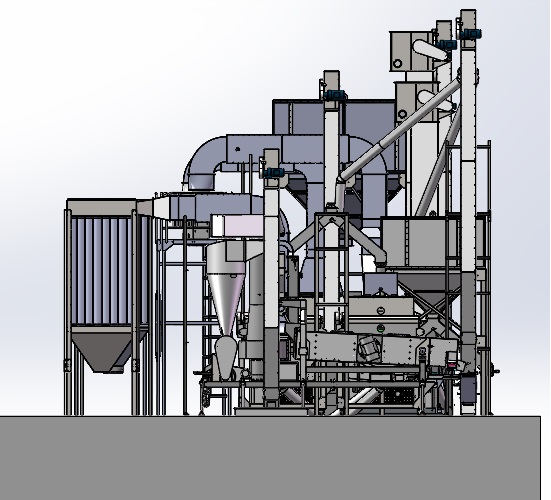

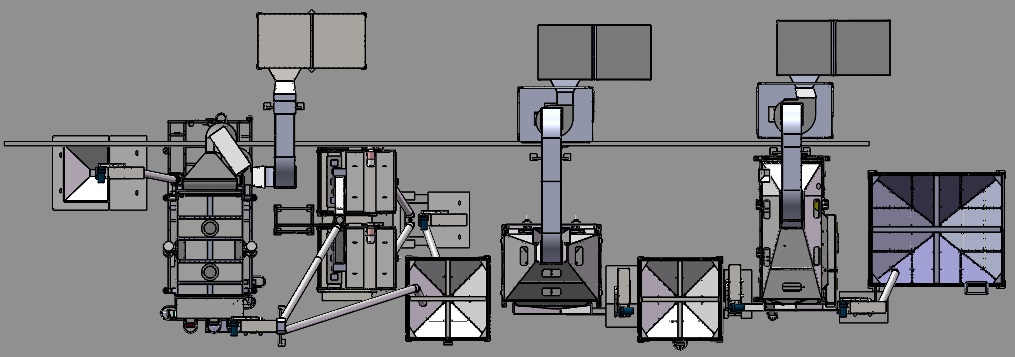

Layout of sesame cleaning plant

Features

● Easy to operate with high performance.

● Environmental cyclone duster system to protect clients warehouse.

● High quality motor for seeds cleaning machine, high quality Japan bearing.

● High Purity :99.99% purity especially for cleaning sesame, groundnuts beans

● 2-10 Ton per hour cleaning capacity for cleaning different seeds and clean grains.

Each machine showing

Air screen cleaner

To remove large and small impurity, dust, leaf, and small seed etc..

As the pre-cleaner in the sesame processing line

De-stoner machine

TBDS-10 De-stoner type blowing style

Gravity destoner can remove the stones from sesame, Beans Groundnuts and Rice with high performance

Magnetic separator

It remove all metals or magnetic clods and soils from beans, sesame and other grains. It is very popular in Africa and Europe.

Gravity separator

Gravity separator can remove the blighted seed, budding seed, damaged seed, injured seed, rotten seed, deteriorated seed, moldy seeds from sesame, Beans Groundnuts and with high performance.

Polishing machine

Function : The polishing machine it will remove the surface dust from the beans surface and mungs beans surface make the beans more shining.

Color sorter

As an intelligent machine, can detect and remove mildewy rice, white rice, broken rice and foreign matters like glass in the raw material and classify rice based on the color.

Auto packing machine

Function :The auto packing machine used for packing the beans, grains, sesame seeds and maize and so on, From 10kg-100kg per bag, electronic controlled automatic

Cleaning result

Raw soya beans

Injured beans

Bigger impurities

Good beans

Technical specifications

| No. | parts | Power (kW) | Load rate % | Power consumption kWh/8h |

Auxiliary energy | remark |

| 1 | Main machine | 40.75 | 71% | 228.2 | no | |

| 2 | Lift and convey | 4.5 | 70% | 25.2 | no | |

| 3 | Dust collector | 22 | 85% | 149.6 | no | |

| 4 | others | <3 | 50% | 12 | no | |

| 5 | total | 70.25 | 403 |

Questions from clients

What is the different between single cleaner with whole processing plant ?

For the single cleaner it can remove the dust and light impurities, it can remove 99% impurities, But for the same size of the stones and clods can not remove, so we need the professional machine for remove the stones and clods.

For one whole beans and pulses processing plant it has Pre-cleaner, De-stoner, gravity separator, and polishing machine and grading machine, color sorter, auto packing machine.

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our firm's purpose for good. We'll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for China Factory for Pulses And Beans Cleaning Line - Pulses and beans processing plant and pulses and beans cleaning line – Taobo , The product will supply to all over the world, such as: Brunei, Seychelles, New Zealand, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.