The miscellaneous grain destoning machine is a machine that uses the difference in density and suspension speed of granular materials (rice, brown rice, rice, wheat, etc.) and minerals (mainly stones, etc.), and uses mechanical wind and reciprocating motion in a certain trajectory. The screen surface is an impurity removal equipment that separates minerals from granular materials. It is an indispensable key equipment in the rice processing technology.

The stone removal equipment is based on the difference in the proportion of crops and stones in the grains, and adjusts parameters such as wind pressure and amplitude to make the stones with a larger proportion sink to the bottom and move from low to high against the screen surface; the grains with a smaller proportion are suspended. It moves from high to low on the surface to achieve the purpose of separation. The stones will also separate and slowly flow out after gathering stones to achieve the purpose of stone removal.

The equipment uses vibration motion to adjust the air flow and adjust the inclination of the screen surface to separate grains and sand. It is a granular body composed of particles with different particle sizes and specific gravity. When subjected to vibration or moving in a certain state, various Particles are divided into different levels according to their specific gravity, particle size, shape and surface state.

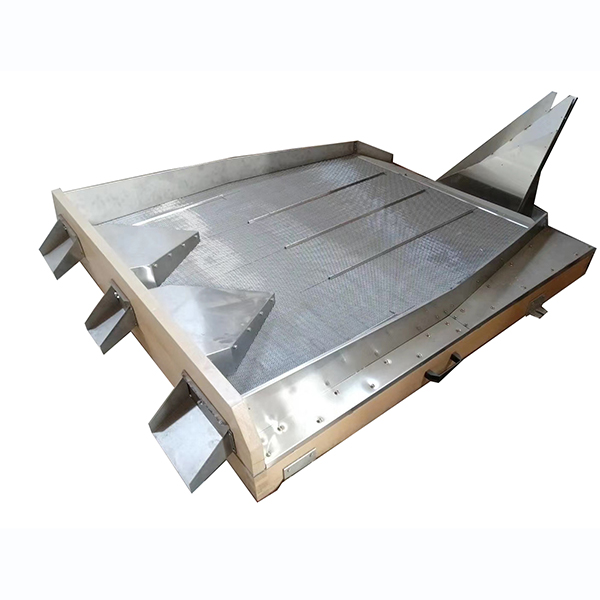

The destoning machine consists of a stainless steel feed suction device, a hopper, a suction hood, a screen body, an eccentric transmission, a rocking mechanism, a frame and other parts. They are all made of stainless steel. The hinges of the reciprocating rocking mechanism of the equipment are Made of rubber, there is no gap between the shaft and the hole, and it uses elastic torsion and swing. The rubber spring is made of imported rubber, which is durable and can absorb vibration. This machine has smooth movement, firmness and reliability, low vibration and low noise. It absorbs air on the stone removal screen plate and no dust is blown out. It adopts a larger air suction hood and suction port. The negative pressure on the stone removal screen plate is similar in size. The wind force passing through the stone screen is uniform.

Grain crops are graded and stoned, and can also be used for seed cleaning. This machine uses the principle of wind, vibration, and sieving to have high production efficiency, good performance in grading, sandstone, and mud removal, low energy consumption, and no dust. It has the characteristics of wide spread, low noise, easy operation, use and maintenance. The use of this machine requires an independent wind net; its effect is more stable and outstanding.

With the development of society, cereals have attracted more and more attention. In the future, the demand for cereals will be greater and the development prospects will be broader. The miscellaneous grain stone removal machine is a common equipment for miscellaneous grain processing to remove stones and heavy impurities in miscellaneous grains according to the different volumes and weights of miscellaneous grains. Its principle is based on the different proportions and suspension speeds of miscellaneous grains and impurities, with the help of upward airflow. Separate miscellaneous grains from side stones, heavy impurities from light impurities, thereby achieving the purpose of classifying heavy impurities and light impurities and removing stones, mud and sand from miscellaneous grains.

Post time: Oct-30-2023