Key words: Mung beans polishing machine; soybeans polishing machine; red bean polishing machine; kidney polishing machine.

Polishing Machine Applications:

Polishing machine is a new type of simple grain cleaning and processing equipment. It is widely used in the grain processing industry, especially the processing and polishing of beans. Polishing machine is to polish beans or grains to make them shiny and good appearance,and grind and remove the beans eaten by insects, and remove the corn stalks to increase the added value of the product. The products processed by this equipment are bright and clear, with good finish, and the quality of materials is further improved.

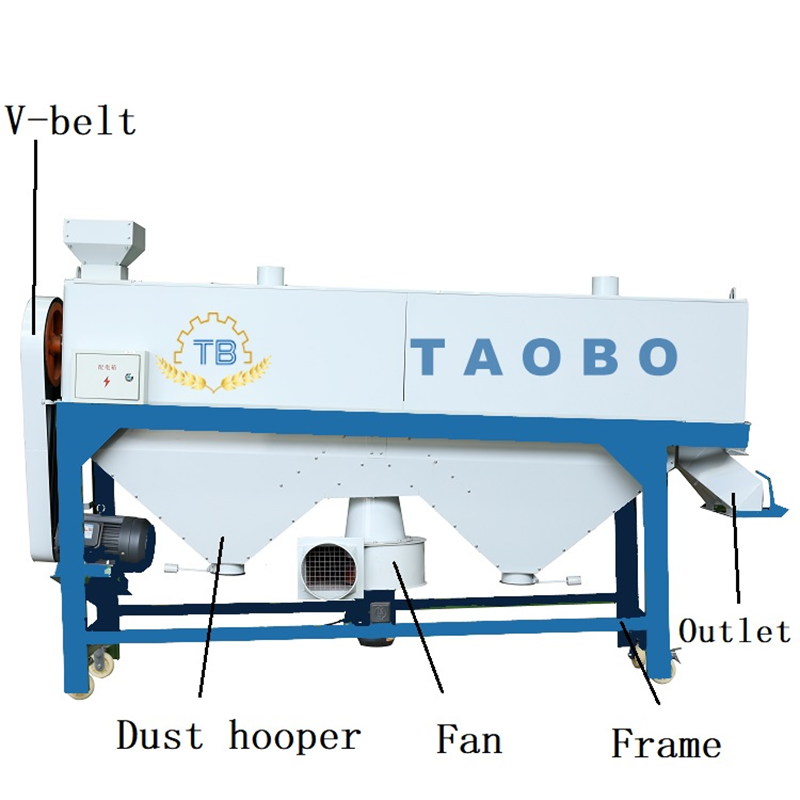

Polishing Machine Structure:

Beans polishing machine consists of feed hopper, stainless steel mesh grid, high quality white canyas, polisher axis, fan and discharge hole. And the function of pure cotton canvas can remove the dust in all kinds of bean’s surface and polishing the materials. It can also remove corn’s top sundry.

Polishing Machine Processing Works:

The material enters the fuselage cylinder from the feed port. Since the canvas is spirally distributed, the canvas core moves in a spiral line with the rotation of the mandrel, thereby pushing the material forward, and at the same time, the surface of the material is smoothed by the canvas. The finished product flows out from the outlet, dust and light impurities are extracted by the fan, and other impurities are discharged into the dust removal hopper through the screen and discharged from the impurity outlet.

Polishing Machine Advantages:

1.The friction of pure cotton canvas can remove the dust in all kinds of bean’s surface and polishing the materials.

2.The cotton canvas material used in the bloom core is low breakage.

3.The polishing machine adopts high quality bearing, they have a longer service life.

4.Easy to move and operate.

5.The selected cleaning rubber ball has the characteristics of high elasticity, cold resistance and aging resistance. It can still be effectively cleaned in winter and improve the permeability of the screen.

Reasonable cyclone dust removal structure, and the installation of a tight rotary dust discharge valve to reduce air leakage, improve dust removal efficiency, and make the working environment cleaner and more environmentally friendly.

Post time: Mar-28-2024