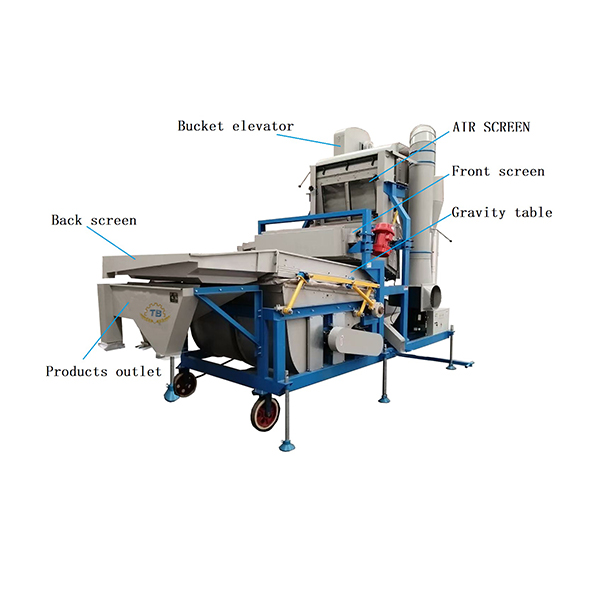

The vibrating air screen cleaner is mainly composed of a frame, a feeding device, a screen box, a screen body, a screen cleaning device, a crank connecting rod structure, a front suction duct, a rear suction duct, a fan, a small screen, a front settling chamber, a rear settling chamber, a impurity removing system, an air volume adjusting system and the like. A machine formed by organically combining a fan and a screening device uses the size characteristics of seeds for screening and the aerodynamic characteristics of seeds for air separation. Widely used in quarries, mines, building materials, coal mines, battlefields and chemical departments for material classification.

The motion of the vibrating air screen cleaner is that the motor drives the vibration exciter with eccentric mass through the V-belt, so that the screen bed vibrates periodically and asymmetrically, so that the material layer on the screen surface is loose and thrown away from the screen surface, so that the fine material can fall through the material layer and be separated through the screen hole, and the material stuck in the screen hole is vibrated out, and the fine material moves to the lower part and is discharged through the screen.

Product features of vibrating air screen cleaner;

1. The frame adopts fully assembled structure, which is convenient for transportation and installation.

2. The vibration exciter adopts cylinder or seat block eccentric structure, the small screen adopts cylinder lubricating oil for self-lubrication, and the large screen adopts seat circulating oil for lubrication.

3. All the joints of the sieve bed are connected by high-strength bolts of steel structure. The unique manganese steel is used to compile the tension installation design of the sieve, which is simple and convenient to replace the sieve and has a long service life.

4. Adopt low-crushing kneading threshing technology to minimize the crushing of corn during threshing.

5. The comprehensive cleaning by air separation and screening ensures the cleaning effect to the maximum.

6. The output is high, and a single thresher can meet the production requirements of the whole production line.

Post time: Feb-02-2023