Vibrating air screen cleaning machines are mainly used in agriculture to clean and sort crops to improve crop quality and reduce losses. The cleaning machine combines two technologies, vibrating screening and air separation, to effectively clean the harvested grains. The following are several applications of air screen cleaners in agriculture:

1. Remove impurities: The air screen cleaner can use the air flow field generated by the fan to disperse the mixture and take away light impurities, such as straw, shells, etc.

2. Improve cleaning efficiency: The vibrating screen makes reciprocating motion driven by the eccentric transmission mechanism. The design of the screen surface helps the material move forward, thereby improving the cleaning efficiency.

3. Reduce loss rate: In view of the problem of high loss rate and impurity content of certain crops such as sunflower after mechanized harvest, the vibrating air screen cleaning device can effectively reduce this phenomenon and improve the cleaning quality.

4. Adapt to different crops: The wind screen cleaning machine can not only be used for cleaning corn and other grains, but can also be adjusted according to different crop characteristics to adapt to the cleaning needs of a variety of crops.

5. Improve crop quality: By removing impurities and inferior seeds from crops, the air screening machine helps improve the quality of the final product and meet the market's demand for high-quality agricultural products.

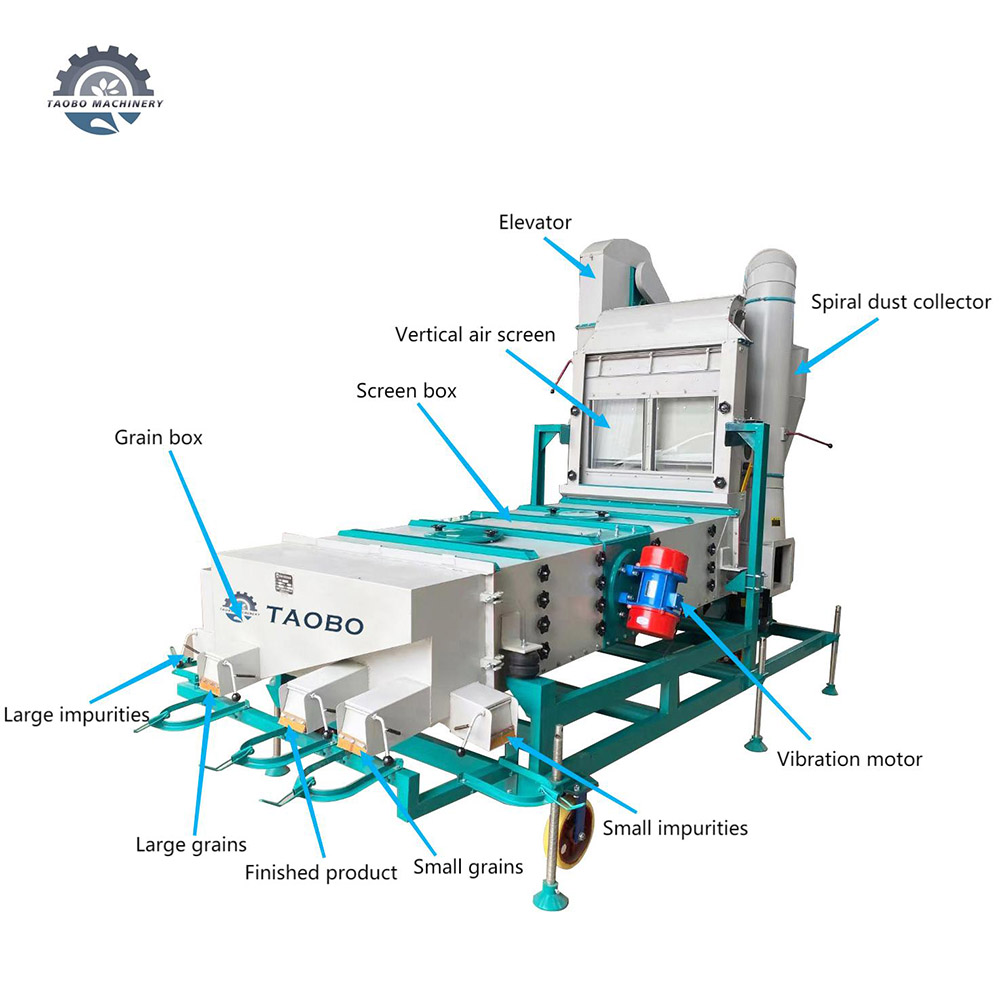

The following are the general characteristics and working principles of the vibrating air screen cleaning machine:

1. Vibrating screening: The air screen cleaning machine uses vibrating screening to screen materials through vibration force. Vibrating screening can effectively separate granular materials into particles of different sizes, thereby achieving the purpose of cleaning and classification.

2. Wind separation: In addition to vibrating screening, the air screen cleaning machine also uses wind power for separation. Through the action of wind, light impurities (such as weeds, leaves, etc.) in the granular materials can be blown away, thereby cleaning and purifying the materials.

3. Multi-layer screen structure: Air screen cleaning machines usually have a multi-layer screen structure. Each layer of screen has a different aperture, which can separate coarse, medium and fine particles and improve sorting efficiency and accuracy.

4. Flexible adjustment: Users can adjust vibration amplitude, vibration frequency, wind intensity and other parameters according to the characteristics and needs of the materials to achieve the best cleaning and sorting effects.

5. High efficiency and energy saving: Vibrating air screen cleaning machines are usually characterized by high efficiency and energy saving. They use advanced vibration and wind separation technology to reduce energy consumption and improve production efficiency.

Post time: Jun-26-2024